Novoalekseevskoye village, Geologicheskiy lane, 1

IN TOUCH

Fill in the feedback form and we will get back to you as soon as possible!

OUR PRODUCTS

AREAS OF USE

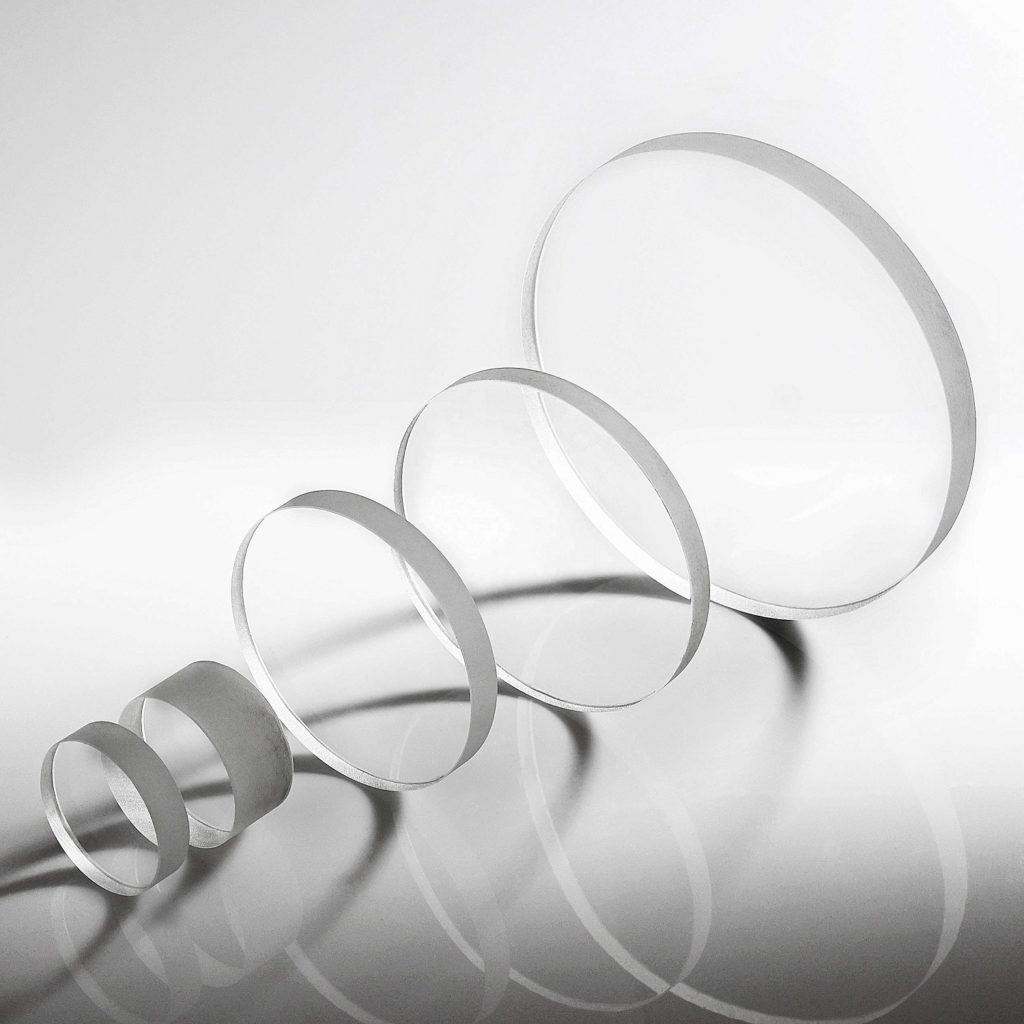

diffusion reactors (tubes) in which high-temperature chemical processing of silicon wafers takes place, cassettes in which silicon wafers are inserted during their processing, cone caps, rings and other types of high-purity quartz glass products.

Clear quartz glass tubes for high temperature mercury, gas discharge, xenon, halogen, ultraviolet, special purpose lamps, thermocouples, semiconductor products, waveguide fixtures and other high temperature devices.

Quartz crucibles are used in the solar industry and the semiconductor industry to smelt single crystal silicon using the Czochralski process.

Silicon is used in the manufacture of integrated circuits, diodes, transistors, solar cells, photodetectors, etc., and lenses in infra-red technology. Silicon is used as an alloying agent in the production of steel and non-ferrous alloys.

Support tubes for light guides, quartz rods and tubes for exhaust and tooling, and large diameter quartz tubes for special furnaces. Quartz glass is widely used in optics, especially in photometry and spectroscopy. It is used to make measuring equipment, plates, UV lamps, optical lenses, microscopes and sight glasses as well as laser lenses and mirror prisms.

Glass with high light transmission is used in the solar energy industry (solar cell production), in the manufacture of products for aviation (category I) and transport, in shop windows, furniture, as interior solutions and for other purposes (category II).

Quartz agglomerate kitchen worktops have gained popularity in the early years of this century. In addition to worktops, quartz agglomerate is used as a facing material for interior interiors, in the manufacture of kitchen and other types of worktops, as well as a variety of furniture and interior components. High durability and wear resistance of quartz agglomerate allows using it not only for residential premises, but also for public buildings. This material has proven itself as an excellent cladding material for sanitary facilities, sales halls and halls, for floors and steps in shopping and leisure centres, railway stations and airports.

Quartz sand for water purification is considered to be excellent. Thanks to its irregular surface, the component absorbs small particles, dust, micro-organisms and small impurities, namely:

- Removes iron, manganese, chlorine and aluminium from water;

- Reduces the amount of radionuclides;

- Absorbs heavy metal ions: cesium, lead, iron, copper and cadmium;

- Cleanses pesticides, nitrates and dioxins;

- Fights bacteria and viruses;

- Neutralises fungus, parasites and algae.

When it comes to foundry and moulding applications, where specific requirements are placed on the materials used in this area. First of all, high quality and good fluidity, thanks to which it is possible to ensure better filling of the model cavities during the vibration process. During shaping, no dust should accumulate on the raw material and the humidity should not exceed 1%. Special attention should be paid to the fire resistance of the raw material, which should be higher than the temperature of the white-hot metal being poured. At the same time, it is better to choose a material that is economical and safe for health. Quartz sand corresponds to all of the above characteristics.

Floors with quartz sand are very hard, hard-wearing and durable and are therefore often used in areas where the floors are under heavy load (workshops, warehouses, etc.).

FIELD HISTORY

In 1940 the Ural office of the trust №13 was transformed to Middle Ural Expedition, and from 15th of June 1962 to expedition №101 with the purpose to discover the deposits of piezoquartz in Middle Urals.

LET'S GET IN TOUCH

Do you have a question or would you like an estimate?

Fill in the feedback form and we will get back to you as soon as possible!